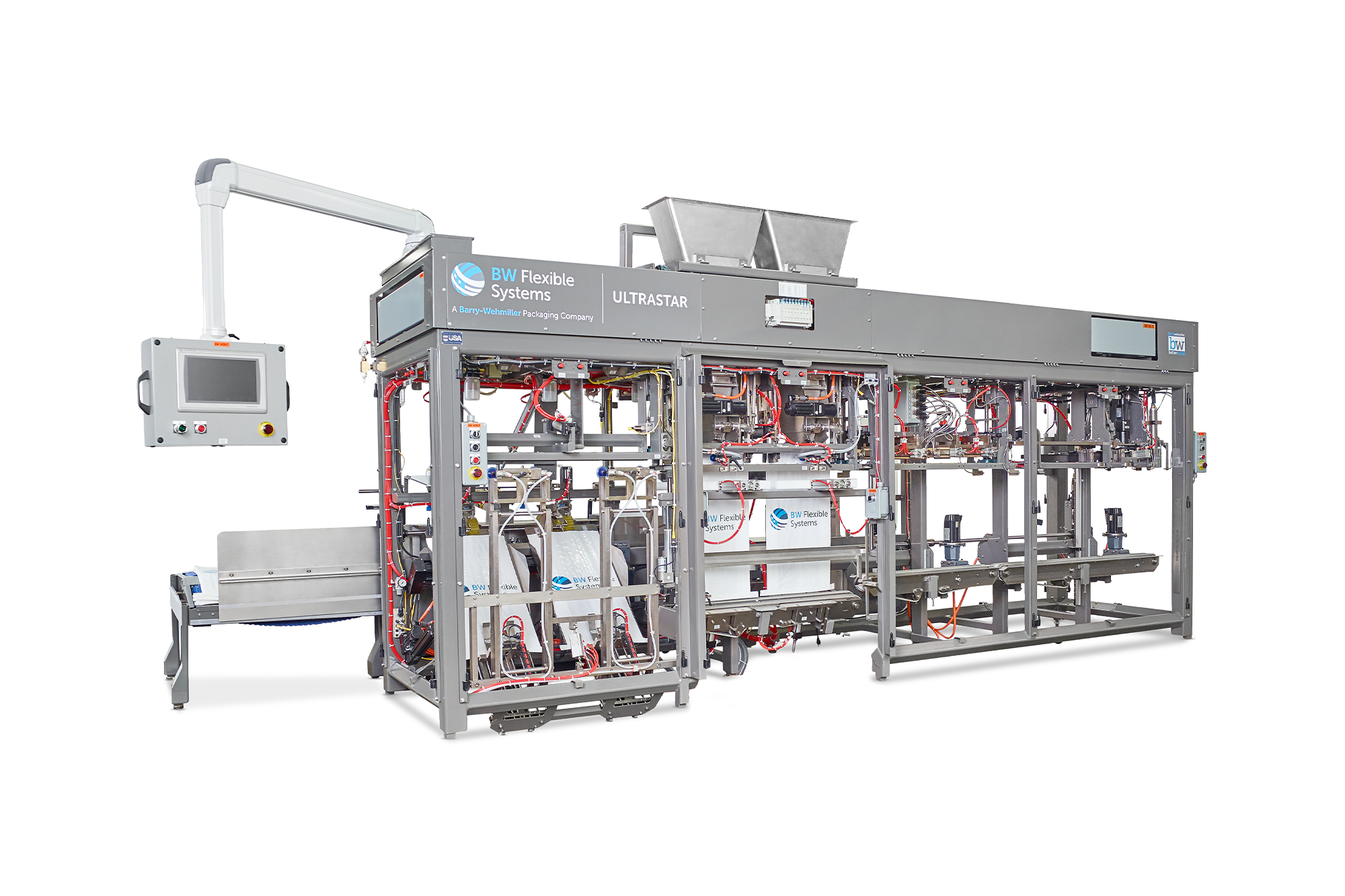

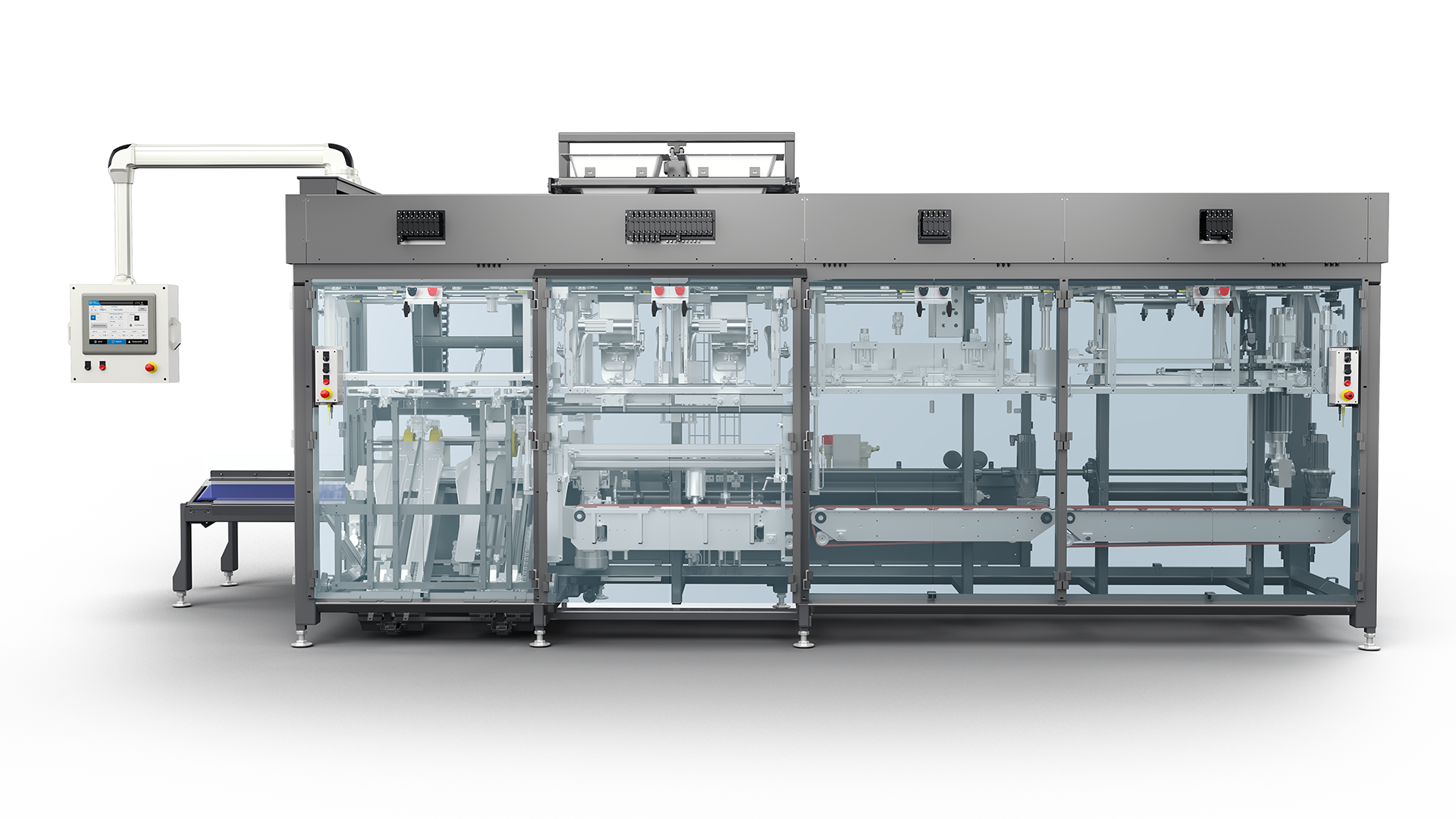

UltraStar G2 Bag Filling System

About this machine

The Thiele UltraStar G2 Bag Filling System offers production-enhancing features for large bags that were formerly found only on packaging systems for small bags. The UltraStar G2 is ideal for industries where speed and line efficiencies are critical. The system can package mid to large sized bags of product at speeds up to 38 bags per minute.

Seamlessly combining sealers, scales, and bag hangers into a unified entity, the UltraStar G2 redefines efficiency and performance. Experience the future of bagging with a system that has been engineered to future-proof your packaging line.

Product Details

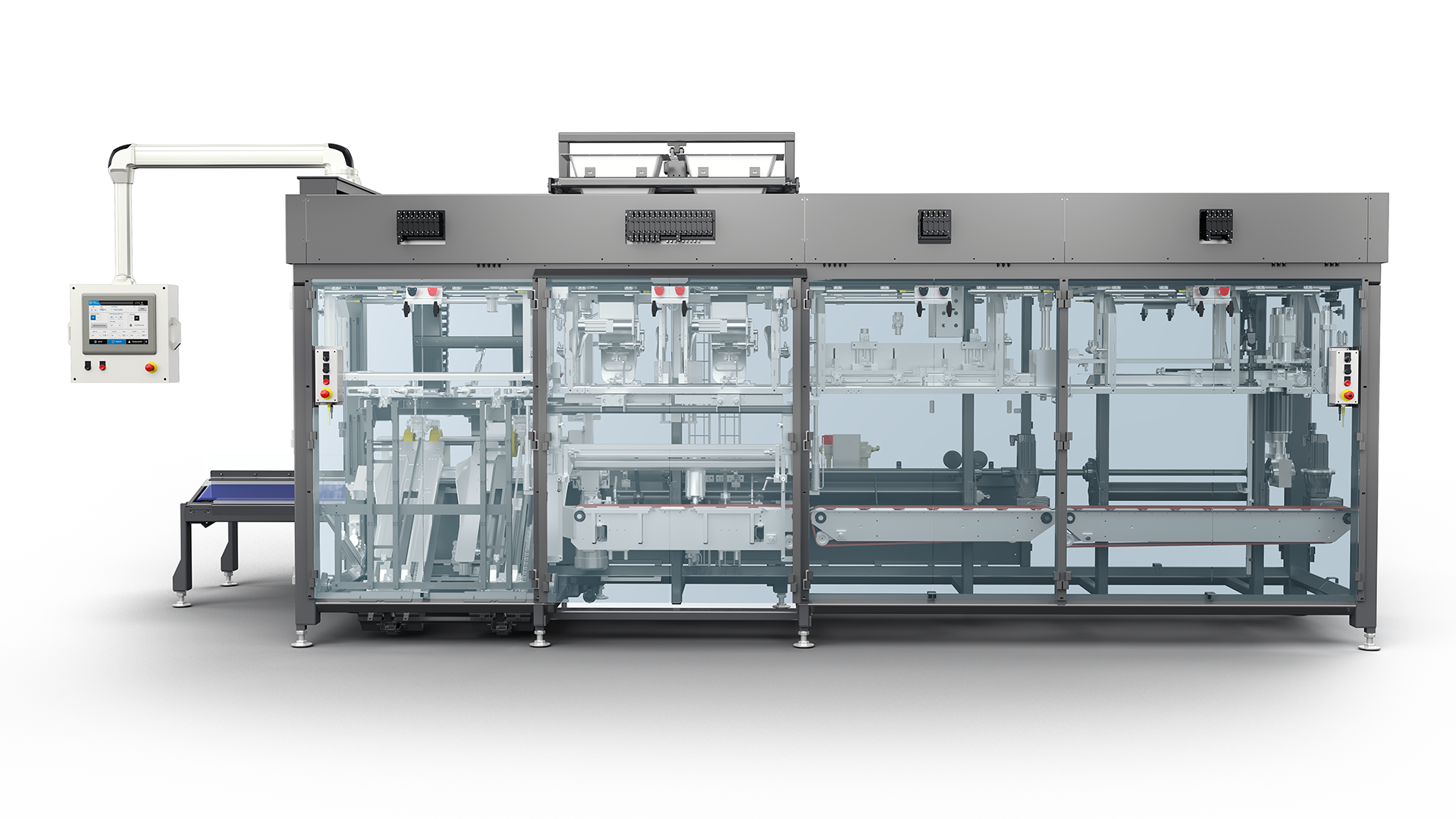

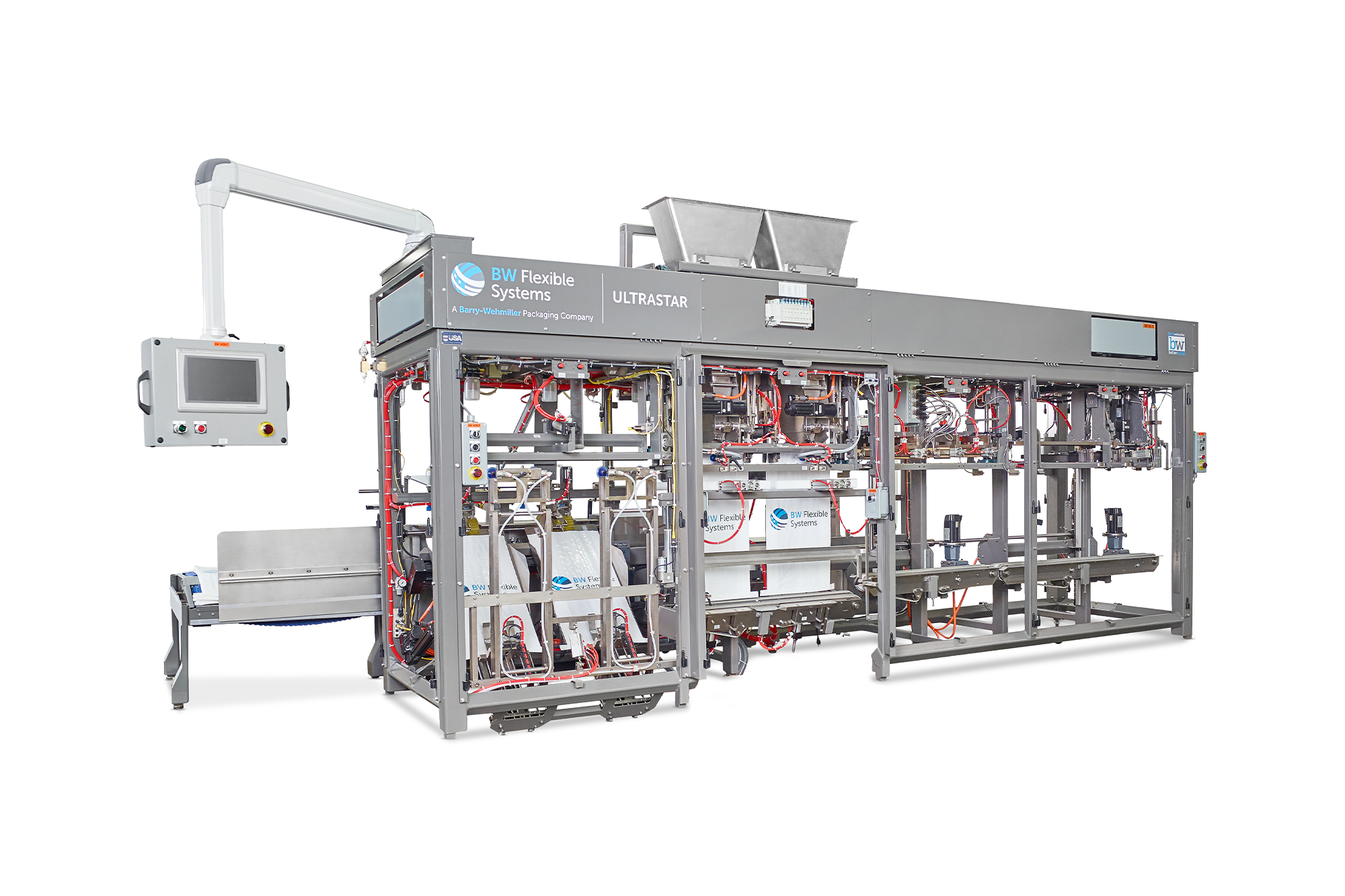

Improved Reliability

The re-engineered Thiele UltraStar G2 bagger contributes to enhanced reliability as it reduces down-time by preventing maintenance and unplanned production stops. The result is a smoother, more consistent packaging operation with higher OEE.

Maintenance Efficiency

To streamline the bagger, we reduced the variety of parts and made the UltraStar G2's design more accessible; this means quicker replacements, minimized downtime, smaller parts inventory, and reduced maintenance costs.

Longevity & Investment

Based on customer feedback and an in-depth analysis of recurring break/fix challenges, transformative upgrades have been made across the UltraStar G2 bagger to maximize value over time and optimize ROI.