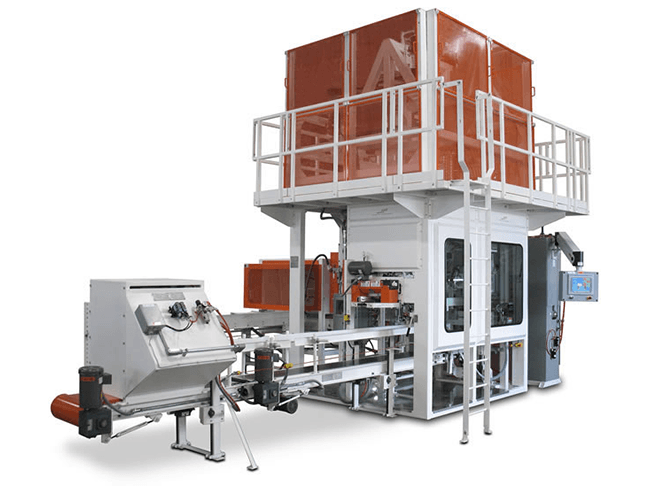

7116 Bag Packer

.png?sfvrsn=c1eb575f_3)

.png?sfvrsn=c1eb575f_3)

About this machine

The Thiele 7116 Packer is a completely automatic, integrated bag packaging system that offers bag feeding, registration and positive bag opening, dual auger product handling and bulk filling, vibratory top-off station, and positive bag control throughout the system.

The 7116 Packer features a dual bulk and dribble auger feeder system that is designed to handle a variety of products, including many hard-to-handle products.

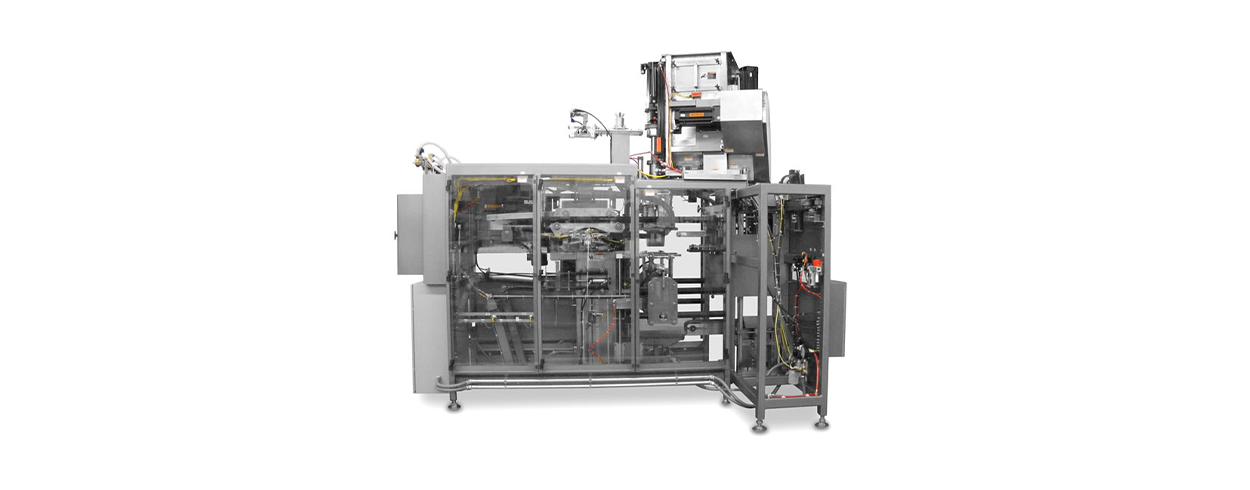

7116 Packer Variations

The Flour packer features a feeder section with interchangeable feeders that is designed to handle a variety of flour products. The bulk feed dual auger system and vibratory top-off is able to feed free-flowing products while maintaining speed and accuracy.

The Mix packer features a feeder section with interchangeable feeders designed to handle a variety of food and bakery mix products. The dual bulk and dribble auger feed system is capable of feeding products with relatively high moisture and fat content.

The bulk fill uses a combination of product agitators, horizontal, and vertical augers to transfer and feed product to the bulk fill station. The vibratory feeder for the top-off station is fed directly form the surge bin.

Product Details

Additional Details & Features

- Completely automatic system

- Inline operation to maintain bag top control

- Integrated, two-stage feed that ensures accuracies and maintains speed

- Positive auger control that handles a variety of products while minimizing dust

- Tube-in-bag filling provides product and dust control

- Automatic fill time adjustments and immediate data

- Removable feeder

- Corrosion resistant

- Automatic bag registration

- Integrated bag settler mechanism

- 304 stainless steel product contact surfaces

Technical Data

Technical Overview

Production Speeds

Up to 10 bags per minute (Packer & Mix Packer)

Up to 12 bags per minute (Flour Packer)

Bag Sizes

Face Width

11 in. - 19 in. (279.4 mm - 482.6 mm)

Length

SOM: 20 in. - 3 ft. (508 mm - 914.4 mm)

PBOM: 21 in. - 3 ft. 1 in. (533.4 mm - 940 mm)

Poly: 14 in. - 3 ft. 4 in. (355.6 mm - 1016 mm)

Woven Poly: 14 in. - 3 ft. 4 in. (355.6 mm - 1016 mm)

Electrical Requirements

Input Power

240/480 volts, 3-phase, 60 hertz

Control Circuit

24 VDC from internal power supply

Current Draw

1.6 scf (45 liters) free air per cycle

Air Requirements

Operating Pressure

80 psi (5.4 atm)

Line Pressure

90 psi (6.1 atm)

Air Use per Cycle

230 volts (20 amps)

460 volts (10 amps)