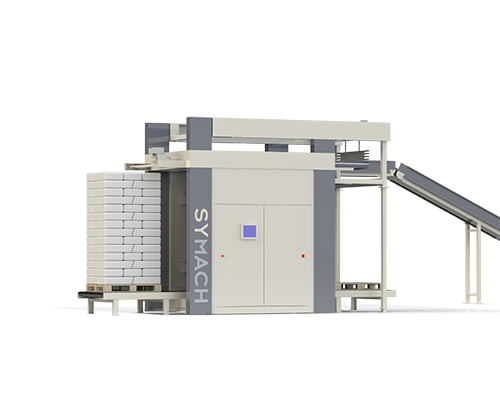

3110 Bag Filling System

About this machine

Thiele's improved 3110 Bag Filling System, formerly Slidell's PowderPacker Pro Vertical Auger Bagging System, is a proven, completely automated packaging system that offers virtually dust free bagging for most difficult to handle powders, especially titanium dioxide, resins and pigments.

This is the ultimate bagging system for:

- Fine, fluffy powders

- Titanium dioxide

- Powdered chemicals

- Talc

- Pigments

Product Details

- Totally automatic - bag placing, feeding, bag top registration, bag opening, weighing , and bag closing, from start to finish , is as easy as pressing a button.

- Complete bag top control offers consistency yet flexibility to run variable length bags.

- Two stage, variable speed, vertical auger feed system virtually eliminates dust for a clean environment.

- Bottom up auger filling eliminates bag deflation, flattening and dust.

- Innovative augers and agitator offer better compression - saves you money by using smaller bags that handle better during palletizing.

- New innovative gross weigh scale design delivers accuracy while reducing wear and maintenance.

- Updated user friendly touchscreen and Allen-Bradley controls make operation easy and minimize learning time and operator error.

Technical Data

Production Speed

- 4-6 bags per minute

Bag Sizes

- Length

- 3835.4 mm (151")

- Width

- 4687.9 mm (184 9/16")

- Height

- 4860.1 mm (191 11/32")

Electrical Requirements

- Input Power

- 460 volts, 3-phase, 60 hertz

- 120 volts, 1-phase, 60 hertz

- Control Circuit

- 24 VDC from internal power supply

- Current Draw

- 230/460 Volts (20/10 amps)

Air Requirements

- Operating Pressure

- 80 psi (5.4 atm)

- Line Pressure

- 90 psi (6.1 atm)

- Air Use Per Cycle

- 1.6 scf (45 liters), free air per cycle