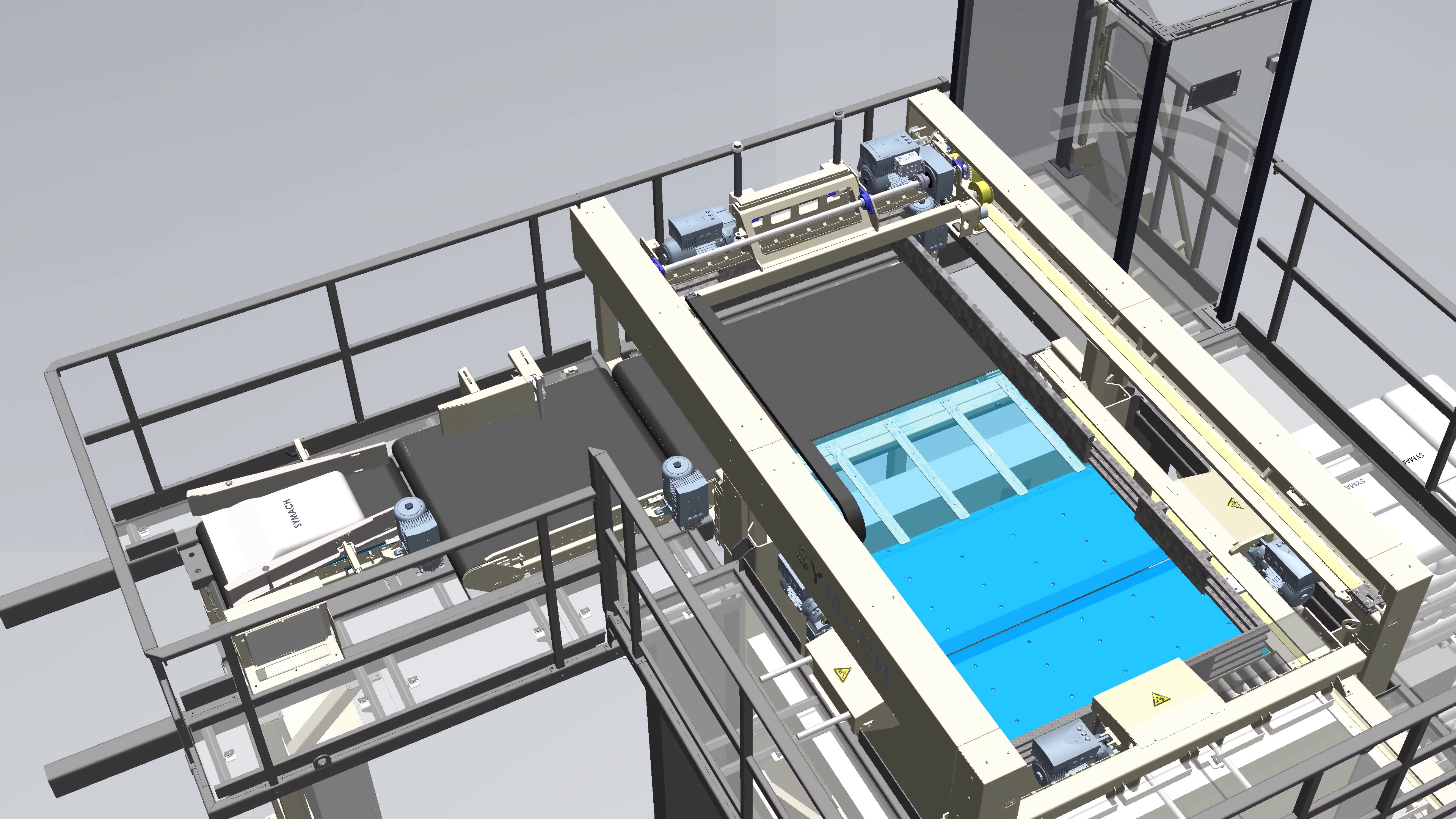

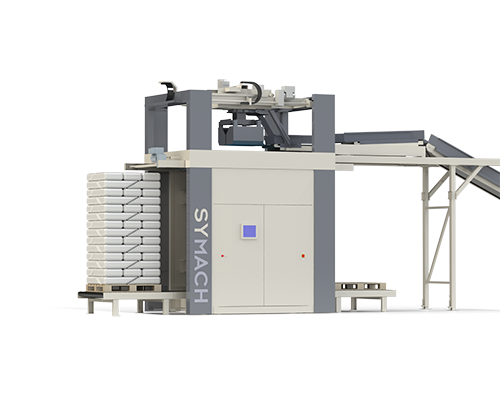

Symach 3500S Palletizer

.png?sfvrsn=2629485f_5)

.png?sfvrsn=2629485f_5)

About this machine

The 3500S Palletizer is your go-to solution for efficient and high-speed palletizing of bags, bales, and cases. Combining the best features of the original 3500 Master palletizer with advanced Thiele & SYMACH technologies, the 3500S is designed to meet your specific needs.

Key Features

- Compact Design: Ideal for tight spaces, the 3500S has a smaller footprint than robotic palletizers.

- High-Speed Performance: Dependable and fast palletizing for various packaging solutions.

- Customizable Options: Tailor your palletizing project with our upstream and downstream options.

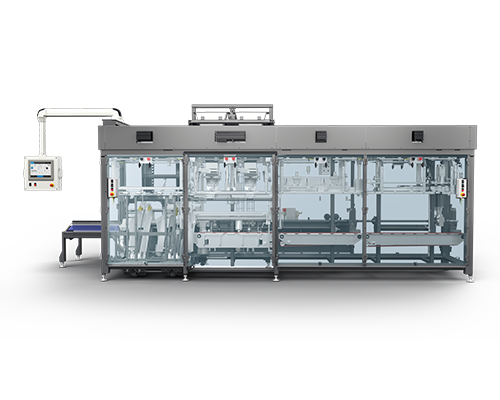

- User-Friendly Interface: Intuitive drag-and-drop HMI for easy operation.

- Robust Build Quality: Next-generation design ensures minimal downtime and optimal cleanliness.

Why Choose the 3500S?

- Space-Saving: Perfect for challenging environments with limited space.

- Versatile Applications: Suitable for a wide range of packaging types.

- Easy to Use: Simplified controls make it easy for your team to operate.

- Reliable and Durable: Built to last with high-quality materials and design.

Contact us today to learn how the 3500S Palletizer can enhance your production line.

Product Details

- 12+ languages standard available

- Connection to an ERP/WMS/MES system for information exchange between the Thiele | SYMACH machines and the customers enterprise and/or control systems

- Pallet transport height (top of roller/chain conveyor): 450mm

- Remote access to the equipment for Thiele & SYMACH technicians (if a network connection is available)

Technical Data

Production Speed

- Up to 40 units per minute

Power Requirements

- 480V, 3 phase, 60Hz

- 480V, 3 phase, 50Hz

Air Requirements

- Standard 7,5 bar (110 PSI)

- Possibility for 5-7,5 bar with the optional booster/buffertank combination

Maximum Load Size

- Length 1600mm x Width 1200mm

Maximum Load Height

- 2150mm / 2400mm / 2650mm

Available Control Systems

- Allen Bradley

- Sigmatek

Ambient Temperature

- +5°C to +40°C