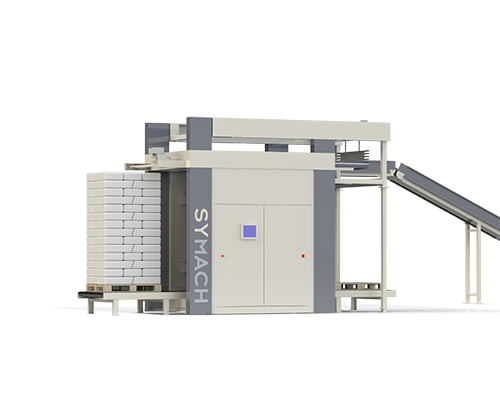

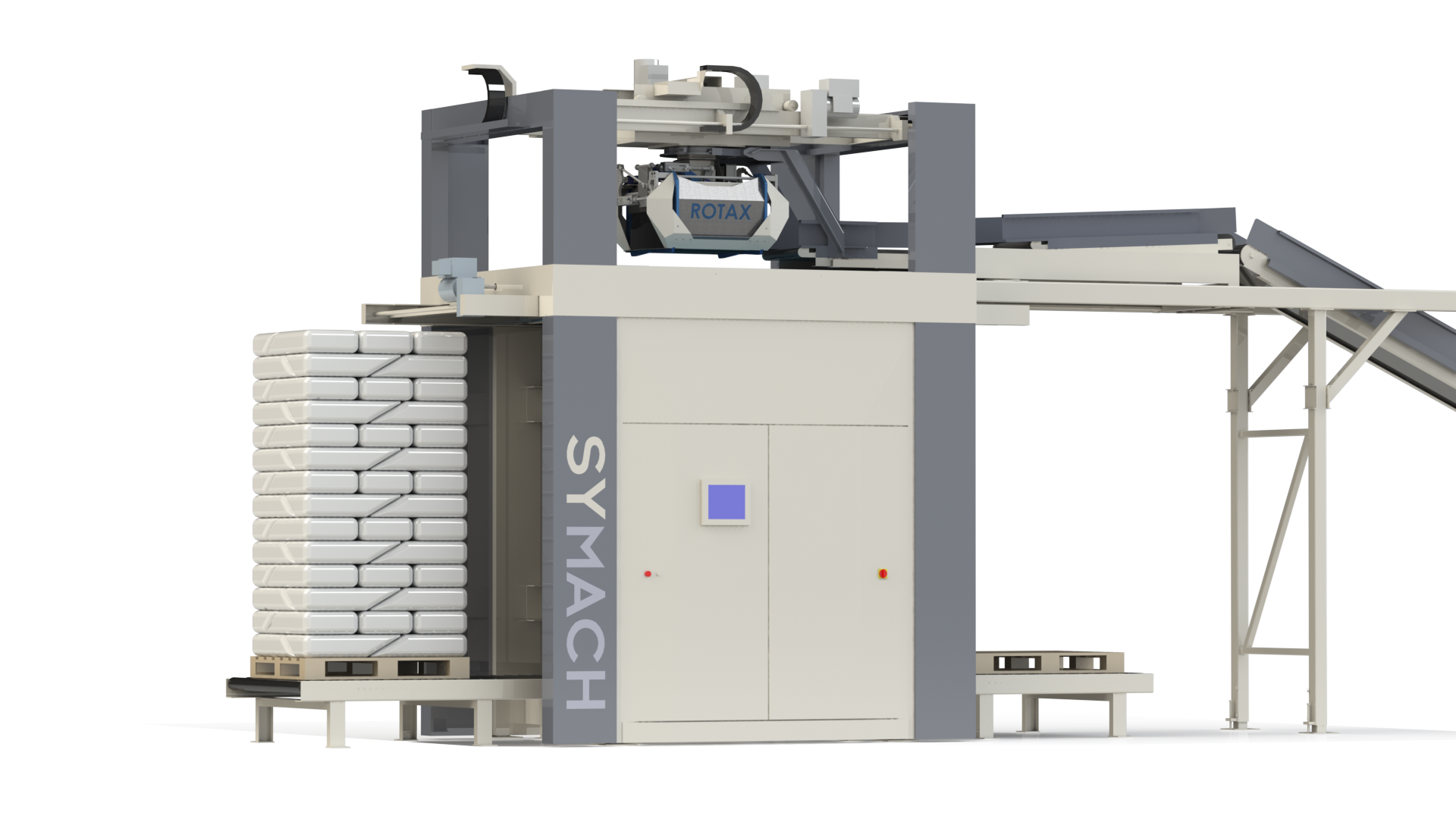

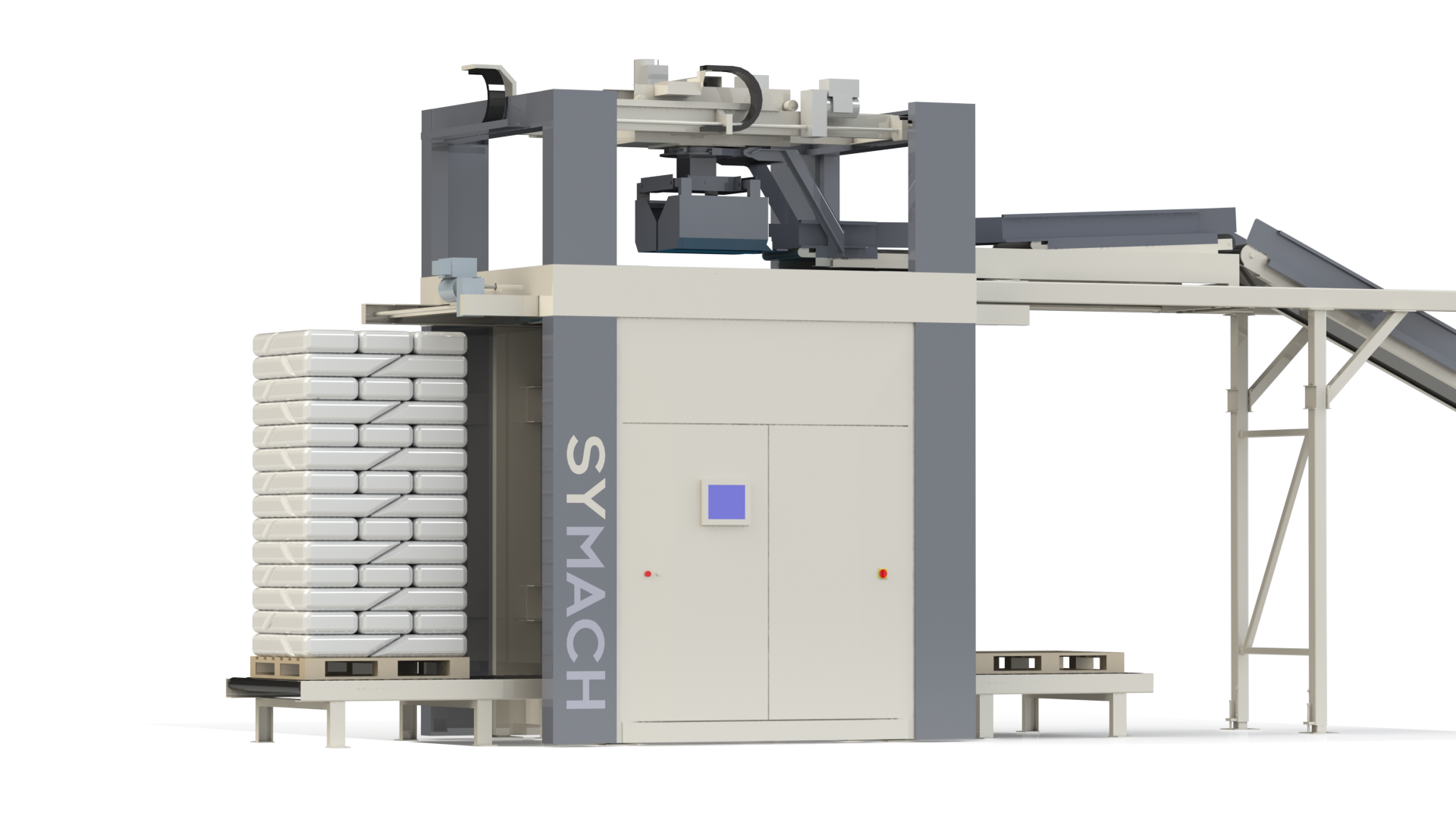

Mach Series Palletizers

About this machine

Symach provides custom-built palletizers for a variety of industries and our Mach Series palletizers lay the foundation for efficient, flexible logistics processes.

"Any palletizer should perform the same." That's the Symach philosophy, meaning that each model should be capable of producing the same level of stacking quality, regardless of speed.

Flexibility is an important feature of Symach palletizers. unlike other palletizer systems, Symach will stack any bag, regardless of type.

Although each model is built up from a standard chassis, Symach engineers have the knowledge and expertise to customize every machine. Symach palletizers can handle the most difficult of products, such as pet food, onions, carrots, potatoes, grass seed, cartons, and bakery products.

Product Details

Unique, Product-Friendly Features

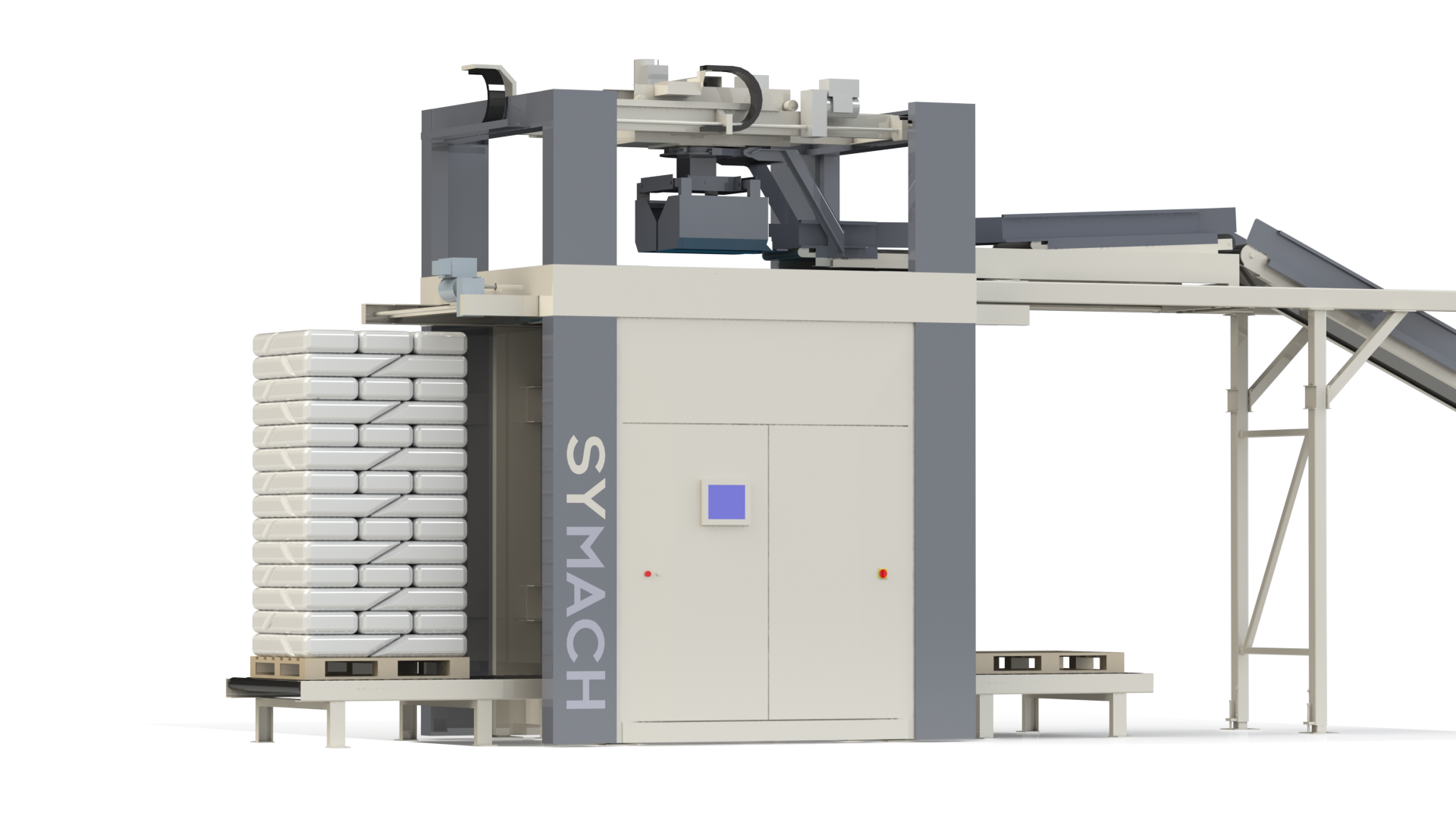

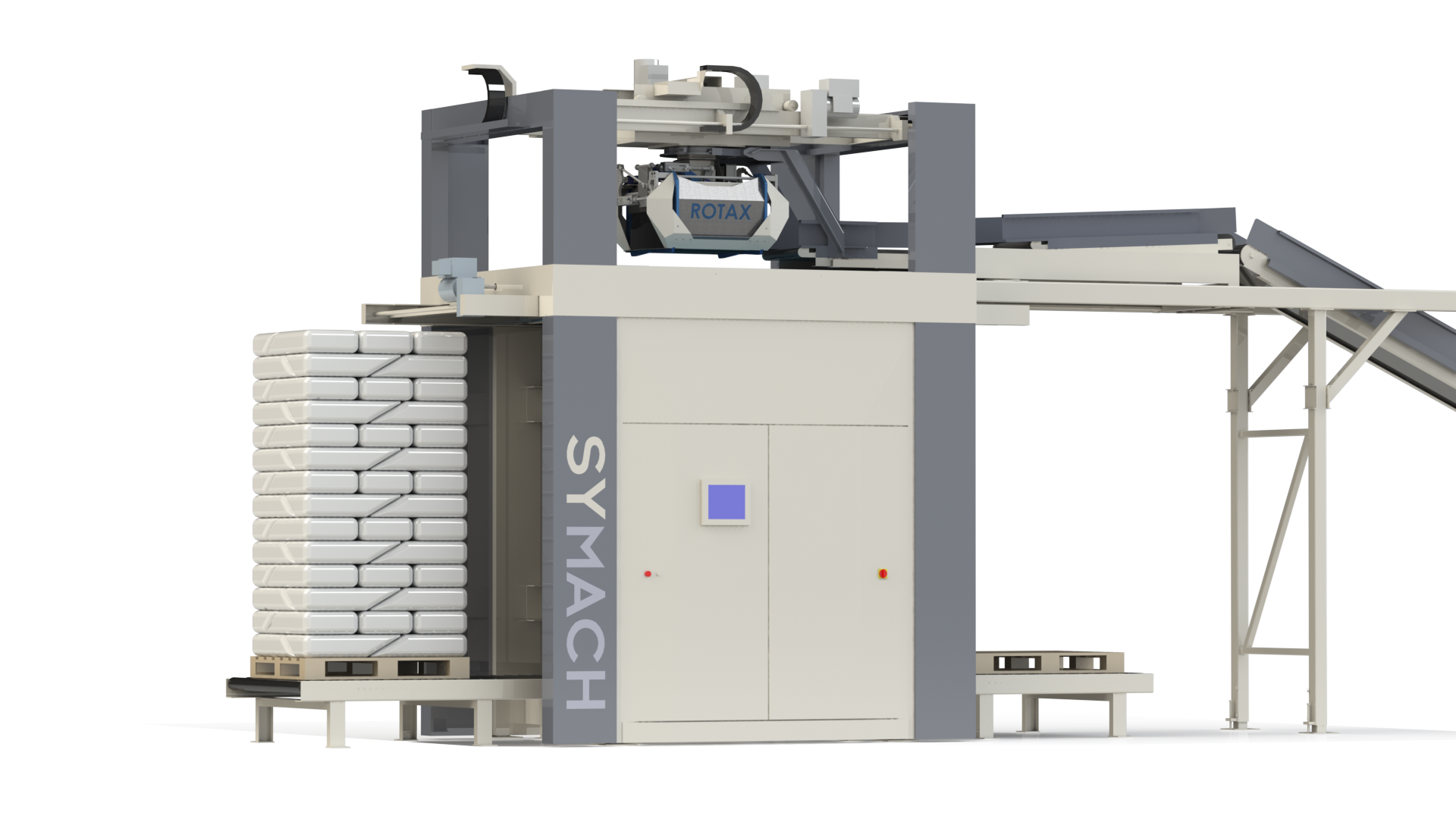

A unique and important feature of the Symach palletizers is the manipulator. It handles each bag individually.

Traditional slide valve systems or grippers occasionally stack inaccurately and can damage packaging. With Symach machines, the bags glide horizontally into the manipulator over a smooth surface.

Once inside, bags are stopped by a fixed final partition and carefully centered. The position of the bag in the manipulator is secured and the bag is released exactly over the programmed position.

This method enables users to stack accurately and with overlaps. Our experience with agricultural products has taught us that this stacking method guarantees the best stability. Other stacking methods are also possible. The manipulator enables customers to realize the most diverse stacking patterns.

- Intuitive drag & drop operation

- Product-friendly handling

- Overlapping of bags

- Straight stacking without product overhang High Efficiency > 95%

- Low Maintenance

Industry-Best Research & Development

Your customers demand high quality presentation. Whether you are dealing with bags of pet food, grass seed, potatoes, or cartons of delicate product, Symach is here to help. We listen to customer needs and work with you to custom build a solution for new and existing machines. Contact our team to build the right palletizer for your unique product needs.

Technical Data

| MACH 2 | MACH 5 | MACH 6 | MACH 8 | |

|---|---|---|---|---|

| Capacity | 13-15 / Minute* | 22 / Minute* | 26/ Minute* | 36 / Minute* |

| Stacking height | 2400 or 2650 mm | 2400 or 2650 mm | 2400 or 2650 mm | 2400 or 2650 mm |

| Operation | Touchscreen | Touchscreen | Touchscreen | Touchscreen |

| Stacking programs | 250 programs / 350 sacks | 250 programs / 350 sacks | 250 programs / 350 sacks | 250 programs / 350 sacks |

| Bag weights | 2,5 - 25 kg and 10 - 50 kg | 2,5 - 25 kg | 2,5 - 25 kg | 2,5 -25 kg |

| Pallet dimensions | All pallet dimensions | All pallet dimensions | All pallet dimensions | All pallet dimensions |

| Machine dimensions | H = 4850 mm L = 4200 mm W = 3000 mm | H = 4850 mm L = 4200 mm W = 3000 mm | H = 4850 mm L = 4200 mm W = 3000 mm | H = 4850 mm L = 4200 mm W = 3000 mm |

| * depending on machine layout | * depending on machine layout | * depending on machine layout | * depending on machine layout |