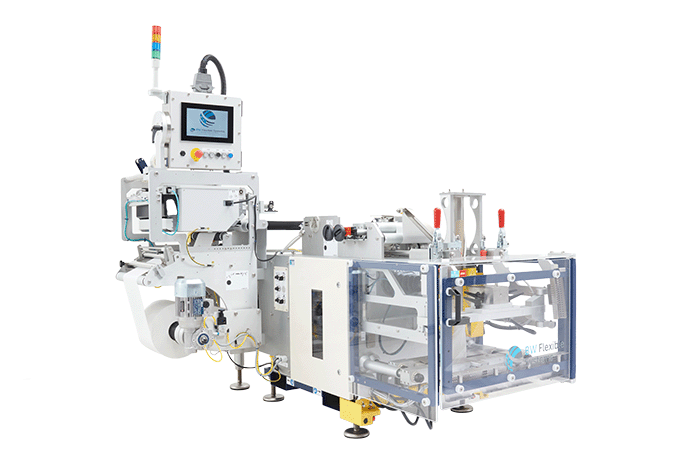

Hayssen Ultima VFFS Machines

About this machine

The Ultima series by BW Flexible Systems offers reliable, customizable VFFS machines designed to meet diverse packaging needs across various industries, including food, medical, pharmaceutical, and pet care. Discover how our Ultima machines can enhance your production line with their advanced features and user-friendly design.

Customizable Options

The Ultima VFFS machine can be tailored to meet your specific requirements, whether you need increased sanitation, higher speed, or other custom features. Here are some of the options available:

- Sanitation Needs: Designed for environments requiring high sanitation standards, with customizable sealing systems suitable for laminate and polyethylene packaging materials.

- High-Speed Efficiency: Capable of forming, filling, and sealing up to 120 bags per minute, with flexible bag sizes to handle a wide range of dimensions.

- User-Friendly Controls: Features an Allen-Bradley interface and control system for easy operation.

- Versatile Performance: Ideal for industries like medical, pharmaceutical, pet care, and food, with intermittent motion technology for production lines where speed isn't the primary goal.

- Heavy-Duty Design: Quieter operation with a robust jaw assembly, ensuring durability and reliability.

- Custom Solutions: Options for integrated zipper applicators, code daters, gas flushing, reclosable seals, inert gas flush, dust extraction, valve fitments, and more.

Why Choose Ultima?

- Durability and Reliability: Proven performance in various industries.

- Customization: Tailored solutions to fit your specific production requirements.

- User-Friendly: Easy-to-use controls and interfaces.

- High Efficiency: Competitive production rates and flexible bag sizes.

Contact BW Flexible Systems today to learn more about how the Ultima VFFS machines can be customized to meet your production needs.

Product Details

Ultima VFFS

- Intermittent Motion Technology: Affordable and efficient for various production needs.

- User-Friendly Controls: Allen-Bradley control system with a color touch screen.

- Heavy-Duty Design: Jaw assembly with shock and noise abatement for reliable operation.

Ultima SVJ VFFS

- High-Speed Efficiency: Servo-driven jaws for faster packaging.

- Advanced Controls: Upgraded Allen-Bradley control system with a color touch screen.

- Robust Design: Heavy-duty jaw assembly with shock and noise abatement.

Ultima SVJ Sanitary VFFS

- Sanitation Focused: Open channel frame and sloped surfaces for easy cleaning.

- High-Speed Performance: Servo-driven jaws for efficient packaging.

- User-Friendly Interface: Upgraded Allen-Bradley control system with a color touch screen.

Technical Data

Ultima VFFS

- Production Rate: Up to 100 bags per minute

- Package Range: Width: 2-1/8” to 16” (54mm to 406mm), Length: 3” to 28” (76mm to 711mm)

- Power Requirements: 230 vac, single phase, 50/60 hz, 20 amp service

- Air Requirements: 2.5 scfm @ 65 psi

Ultima SVJ VFFS

- Production Rate: Up to 120 bags per minute

- Package Range: Width: 2-1/8” to 18” (54mm to 457mm), Length: 3” to 28” (76mm to 711mm)

- Power Requirements: 230/460 vac, single phase, 50/60 hz, 30 amp service

- Air Requirements: 2.5 scfm @ 65 psi

Ultima SVJ Sanitary VFFS

- Production Rate: Up to 120 bags per minute

- Package Range: Width: 2-1/8” to 18” (54mm to 457mm), Length: 3” to 28” (76mm to 711mm)

- Power Requirements: 230/460 vac, single phase, 50/60 hz, 30 amp service

- Air Requirements: 2.5 scfm @ 65 psi