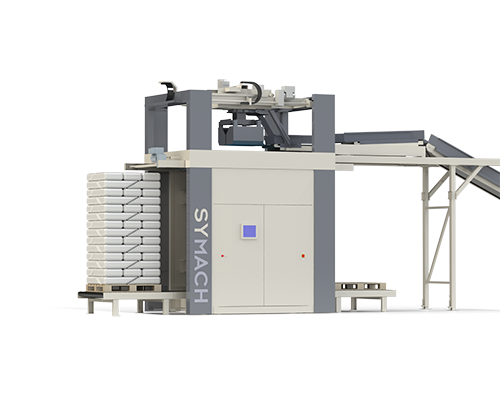

Hayssen Ultima 2236

About this machine

The Ultima 2236 Form, Fill, & Seal System is an integrated large bag packaging system that can handle free-flowing and semi free-flowing products at speeds up to 30 bags per minute to form, fill, and seal large packages from 25 to 50 lbs. (11.3 – 22.6 kg).

Compared to a pre-formed bag system, the Ultima 2236 offers both high speeds and lower operational costs.

And, thanks to a patented measure, pull, and form concept, the Ultima 2236 is low profile while making longer bags. This system also saves valuable space, makes lighter gauge bags, and offers more continuous productivity.

Product Details

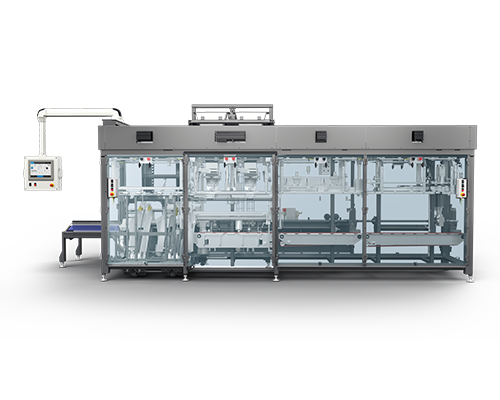

Features & Benefits

- MicroLogix solid state controller

- Roll lift mechanism

- Film splice assist

- Continuous motion hot air back-seam seal

- Static eliminator

- Quali-Seal™ resistance cross-seal system with heated cut-off knife

- Product stager/super collar

- Bag support eject device

- Maintenance alert prevention system

Technical Data

Technical Data

Production Speed

Up to 30 bags per minute

Overall Dimensions

Depth: 10 ft. 8.5 in (3,263.9 mm)

Width: 5 ft. 5.25 in. (1,657.4 mm)

Height: 7 ft. 5.75 in. (2,279.7 mm)

Shipping Weight

6,750 lbs. (3,070 kg)

Electrical Requirements

Input Power: 240/480 volts, 3-phase, 60 hertz

Control Circuit: 24 VDC

Current Draw:

- 20 amps @ 240 volts

- 12 amps @ 480 volts

Air Requirements

Operating Pressure: 80 psi (5.4 atm)

Line Pressure: 90 psi (6.1 atm)

Air Use Per Cycle: 40 SCFM at 30 bags per minute