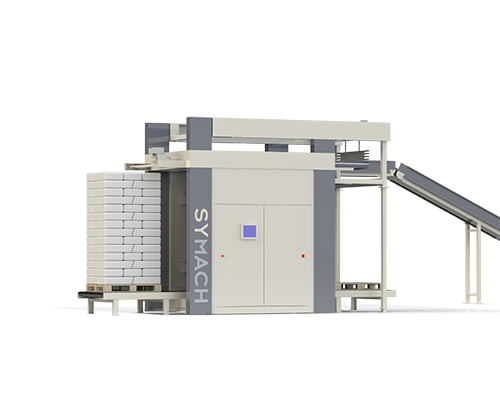

OmniStar Bag Filling Machine

About this machine

The Thiele OmniStar is a high speed bag filling system that offers production-enhancing features for large bags that were formerly found only on packaging systems for small bags. The OmniStar system is ideal for industries where speed and line efficiencies are critical. The system can package mid to large sized bags of product at speeds up to 20 bags per minute.

The Thiele OmniStar Bag Filling Machine has been designed to increase efficiency and accuracy for your bag filling and sealing operation. This system is ideal for a wide variety of industries, as it performs at high-speed and is engineered for quick machine changeovers.

In addition to accurately filling your product bags, these machines can also provide important insights into production downtime and faults. This allows you to monitor and improve your production process.

Product Details

OmniStar Bag Filling Machine Features

- Automatic reject of unsatisfactory bags

- Runs poly, polywoven, and paper bags

- Servo-driven for fast, smooth and precise operation

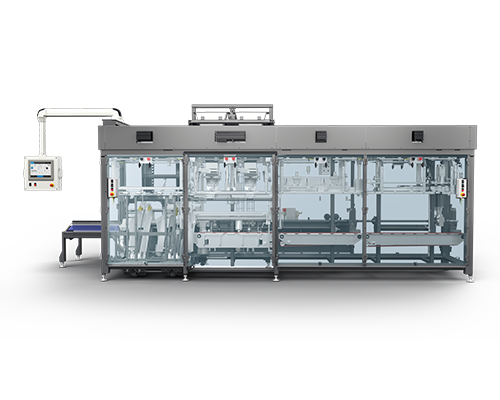

- Fully integrated PLC control system with common HMI for scale and bagger available

- Integral sealing for paper, poly and polywoven bags

- Single filling spout

- Simple design features one-third the number of moving parts as competitive baggers

Key Benefits

- Eliminates spillage

- Reduces downtime

- Provides easier troubleshooting

- Minimizes dusting

- Maintenance reminders

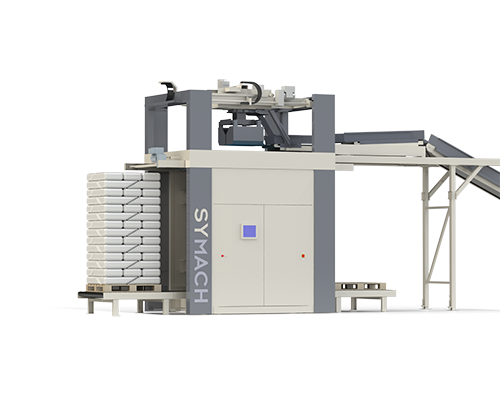

Efficient Operation

The OmniStar bag filling machine has ⅓ of the moving parts offered by our competitors. This means routine machine maintenance is easier and safer for your service technicians. It also helps to decrease machine downtime, as there are less parts needed for it to properly function.

Adjustable Filling Spout

The size of the filling spout's opening varies by product, meaning it needs to be adjustable. Unlike traditional by-hand adjustment methods, the OmniStar filling spout uses a servo motor to open and close the spout.

Automatic Reject of Unsatisfactory Bags

Reduce production errors with OmniStar's automatic rejection system. This system utilizes a MasterWeigh scale to determine the weight of the bag.

If it is under or overfilled, the machine will reject the bag, stopping the faulty package from traveling further down the production line.

Advanced Bag Top Registration System

A correctly positioned bag opening is vital to produce a properly filled and sealed bag. The bag top registration system for the Thiele OmniStar bag filler evaluates and corrects the position of the bag before it's filled. This helps it get filled accurately and assists with minimizing product waste.

Customize the Machine to Your Needs

There are several customizations available for the Thiele OmniStar bag filler. These include systems such as a bar code scanner that can help automate machine changeover, a VPN remote diagnostic system, or a laser bag printer.

Speak with a BW Flexible Systems sales representative to learn more about add-ons that could help you with your production needs.

Bag Air Deflation System

The air inside a product bag can damage the product, as it may cause it to become stale during its journey to its end consumer. This means your consumers will experience reduced product quality, which can negatively impact your brand's reputation.

The air inside a sealed bag can also lead to other issues, such as affecting the way it's transported throughout the rest of the production line or how it's stacked in the pallet.

The OmniStar bag filling system can be equipped with a bag deflating system, which squeezes the air out of the bag before being sealed.

Quick Changeovers

The frame and operation of the Thiele bag fillers was designed to be easily accessible and straightforward, so things are less crammed inside. Additionally, the intelligent systems include the ability to program bag "recipes" that the machine can remember.

When the machine operators are ready to switch to a different product, they simply scan a bag barcode. This will signal the machine to make the changeover adjustments itself.

High-Speed Production

This machine uses a single filling spout to fill up to 20 mid-to-large sized bags per minute. This assists with improving the speed of your overall production, meaning you get more out of your machine runtime.

Versatility Across Industries & Materials

The Thiele OmniStar can be used across multiple industries such as food, industrial & automotive, agriculture, and pet/animal food and care and is suitable for use with multi-wall paper, poly, polywoven, and polyethylene non-gusseted bags.

Technical Data

Production

- Up to 20 bags per minute

Bag Sizes

- Face Width: 279 to 483mm (11" to 19")

- Length:

- PBOM: 381 to 1041mm (15" to 41")

- SOM: 355 to 1016 mm (14" to 40")

- Poly: 355 to 1016 mm (14" to 40")

- Woven Poly: 355 to 1016 mm (14" to 40")

Power Requirements

- Input Power: 230/460V, 3-phase, 60 hz

- Control Circuit: 24 Volt DC form internal power supply

- Current Draw: 230 volt (20 amps), 460 volt (10 amps)

Air Requirements

- Operating Pressure: 80 psi (5.4 atm)

- Line Pressure: 90 psi (6.1 atm)

- Air Use per Cycle: 2.0 scf (55 liters) free air per cycle