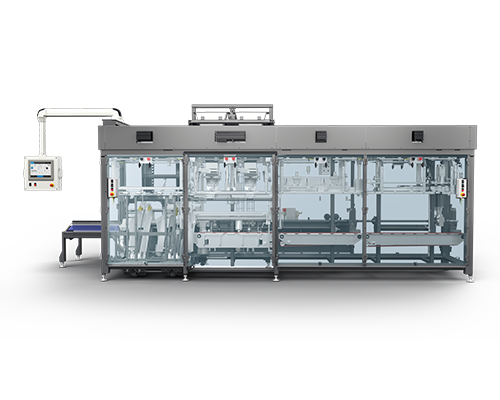

Swinger Bag Filling System

About this machine

The Thiele Swinger Bag Filling System automatically hangs heavy-duty flat tube or gusseted open-mouth poly, paper or poly woven bags. Featuring a “traveling” bag spout that moves to meet the bag pickup assembly, the Swinger Bag Filling System offers speeds up to 18 bags per minute (7107 Swinger) for fully automatic operation or 20 bags per minute for semi-automatic operation (7105 Swinger).

Our Thiele Bag Filling System delivers several key benefits to your bag filling operation.

Key Benefits

- Easily accessible controls

- Simple operation

- Reduced downtime

- Increased accuracy

Product Details

Features

7105 Swinger

- Semi-automatic operation

- Large, easy to load magazine requiring no shutdown for reloading

- Bag magazine automatically indexes next stack of bags

- Automatic no-bag/no-product sensing device prevents product discharge unless bag is in place

- Adjustable loading tray for accurate bag spouting

- Quick and easy adjustments for bag size changes

- Low profile design integrates with most scales

- Allen-Bradley PLC with HMI

- NEMA 12 electrical construction

7107 Swinger

- Fully automatic operation

- Accommodates many types of bags

- Traveling bag spout increases speed up to 20 bags per minute

- Large, easy-to-load magazine with no shutdown for reloading

- Bag magazine automatically indexes next stack of bags

- Automatic no-bag/no-product sensor prevents the scale from dumping product unless a bag is in place on the holder

- Electro-pneumatic controls require little maintenance

- Quick and easy adjustments for bag size changes

- Low profile, easily integrates with most scales

Technical Data

Technical Data Comparison

| 7105 Swinger | 7107 Swinger | |

|---|---|---|

| Production | ≤20 bpm | ≤18 bpm |

| Bag Sizes | Face Width: Gusset: 355.6 – 508 mm (14" – 20") Flat Tube: 355.6 – 609.6 mm (14" – 24") | Face Width: Gusset: 254 – 558.8mm (10" – 22") Flat Tube: 305 – 609.6mm (12" – 24") |

| Bag Lengths | Gusset: 635 – 1041.4 mm (25" – 41") Flat Tube: 635 – 1041.4 mm (25" – 41") | Gusset: 635 – 1016mm (25" – 40") Flat Tube: 635 – 1016mm (25" – 40") |

| Power Requirements | Input Power: 240/480 VAC, 3-phase, 60 hz, 30/15 amps Control Circuit: 24 VDC form internal power supply Current Draw: 240 volt (10 amps), 480 volt (5 amps) | Input Power: 240/480V, 3-phase, 60 hz, 30/15 amps Control Circuit: 24 VDC form internal power supply Current Draw: 240 volt (10 amps), 480 volt (5 amps) |

| Air Requirements | Operating Pressure: 80 psi (5.4 atm) Line Pressure: 90 psi (6.1 atm) Air Use per Cycle: 1.0 cubic ft. (28.32 liters) | Operating Pressure: 80 psi (5.4 atm) Line Pressure: 90 psi (6.1 atm) Air Use per Cycle: 1.0 cubic ft. (28.32 liters) |